Variomatic

| Transmission types |

|---|

| Manual |

| Automatic |

| Bicycle gearing |

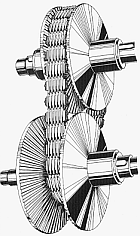

Variomatic is the continuously variable transmission (CVT) of the Dutch car manufacturer DAF, originally developed by Hub van Doorne:[1] It is a stepless, fully automatic transmission consisting of a "V" shaped drive belt and two pulleys, each of two cones, whose effective diameter can be changed so that the "V" belt runs nearer the spindle or nearer the rim, depending on the separation of the cones. These are synchronized so that the belt always remains at the same optimal tension.

History

It was the first commercially successful CVT (as opposed to shifting between separate gears). In theory, this always produces the optimum torque. The Variomatic was introduced by DAF in 1958, also putting an automatic gear box in the Netherlands for the first time. The variomatic was introduced on the DAF 600.

Efficiency

Due the fact the engine runs most of the time in its best fuel economic speed, the fuel consumption of this car was at accepted level, although the fuel efficiency of any mechanical CVT is about 70 (then) to 75% today (Bosch).

Reversing

Because the system does not have separate gears, but one (continuously shifting) gear and a separate 'reverse mode' (as opposed to a reverse gear), the gear works in reverse as well, giving it the interesting side effect that one can drive backwards as fast as forwards. As a result, in the former Dutch annual backward driving world championship, the DAFs had to be put in a separate competition because no other car could keep up. Thus, these very cheap and simple cars were the 'formula one' in this competition.

Multitronic

Manual transmission remains dominant in Europe. When DAF was taken over by Volvo, the Variomatic patents were transferred to a company called VDT (Van Doorne Transmissie), later taken over by Bosch. VDT continued development of the CVT and introduced a pushband system in the Ford Fiesta and Fiat Uno. Audi reintroduced an improved version of the variomatic in 2000 under the name multitronic. This system uses a metal belt and lacks a limit to the number of gears available, switching between them without noticeable shocks. These metal drive belts are the most important part of CVT. There are three factories producing these belts, the Bosch factories in Tilburg (the Netherlands), Ho Chi Minh City (Vietnam), and San Luis Potosí (Mexico). It is used in over 40 car models, these days even including expensive brands like Mercedes-Benz.

Operation

Gear ratio

The final drive has two pulleys with moveable conical drums. The distance between the drums is controlled by the engine vacuum in the inlet manifold and engine RPM, through centrifugal weights inside the drums. Between the two pulleys runs a drive belt. As a result of change in the distance of the conical drums in both pulleys, the diameters and so also the reduction ratio changes continuously.[2]

Differential

|

Huron-Cosworth H4A hillclimb prototype with Variomatic transmission

|

| Problems playing this file? See media help. | |

With the DAF 600 - 55 each rear wheel was propelled individually by a pair of conical drums and drive belt with the effect of a limited slip differential: if a drive wheel on slippery road revs up, the other wheel can still transfer the full torque. This results in unusually good traction characteristics, which were also a reason for successes of the DAFs in rallies. There were several disadvantages that accompanied the lack of a true differential gear. Although each belt could settle (independent of the other) into its optimum position, thus allowing for wheel speed variation, the system was slow to operate and depended on the pulleys being turned. This led to rapid tire wear and placed stress on other transmission components. Snapped drive shafts were common. Low speed handling in icy conditions was interesting as the system tended to drive the car forward against the influence of the steered wheels. Later cars, the 46, 66 and Volvo variants were fitted with a differentially geared axle. A version with a differential was developed by Williams in the 1993 Williams FW15C CVT Formula One car,[3][4][5] but it was banned before being raced. In testing there were problems with the heat production.[6]

Motorscooters

The Variomatic is also used in today's motorscooters. It is a standard part of all common scooters since 1985, and several companies such as Malossi, Polini, Doppler and Stage6 are offering tuning clutches and variomatic for most common 50, 70 and 125 cc scooters.

Steel link belts

Today the CVT works according to the same principle of split pulleys allowing infinitely variable gear ratios. Rather than the pulled rubber drive belts as originally used by DAF, the modern transmission is made much more durable by the use of steel link belts that are pushed by their pulleys. This update was pioneered by Fiat, Ford and Van Doorne in the Netherlands from the late 1970s. [7] The gearbox is also under electronic control.

The version that contains the switch from rubber to steel belts was called the Transmatic. [8]

Availability

DAF's Van Doorne's Transmissie is still operating (As of Nov 2015) in Tilburg, Netherlands. It changed affiliations from the DAF group to Bosch in 1995. [9]

The CVT is available from brands such as Audi, Honda, and BMW Mini, and is standard on all Subaru models. Tata Motors from India recently announced that it would use a Variomatic transmission in its $2500 Nano.[10] Nissan Primera is offered with this transmission.

Notes

- ↑ "Transmissions drove Hub van Doorne’s innovative spirit", Feb 2009, autonews.com

- ↑ "Belt Drive Shifts Dutch Economy Car." Popular Mechanics, December 1959, pp. 140-142.

- ↑ "Image: williamscvt.jpg, (600 × 386 px)". 8w.forix.com. Retrieved 2015-09-02.

- ↑ "DAF passenger cars". Ritzsite.demon.nl. Retrieved 2009-10-03.

- ↑ 24 april 2007 (2007-04-24). "Formula One with Automatic transmission". YouTube. Retrieved 2009-10-03.

- ↑ Keith Collantine (2007-05-03). "Banned! Continuously Variable Transmission (CVT) | F1 Fanatic - The Formula 1 Blog". F1 Fanatic. Retrieved 2009-10-03.

- ↑ "Gearless transmission - steel pulleys make it automatic" Popular Science, July 1976, pp. 57.

- ↑ "Gearless transmission - steel pulleys make it automatic" Popular Science, July 1976, pp. 57.

- ↑ "Case Study: Keeping pace with the popularity of continuously variable transmission". Siemens.com. 2012. Retrieved 2015-11-03. line feed character in

|title=at position 12 (help) - ↑ "Tata Motors seeks patent protection for Rs 1-lakh car". Autoexpo.in. 2007-11-23. Retrieved 2009-10-03.