VVER-TOI

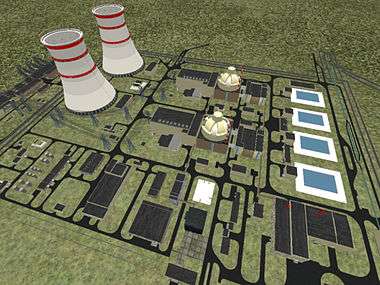

The VVER-TOI or WWER-TOI is a design for a two-unit nuclear power plant.[1] It would use VVER-1300/510 water pressurized reactors constructed to meet modern nuclear and radiation safety requirements.

According to the results of the President Committee session for upgrading and development of the Russian economy of July 22, 2009, the President of the Russian Federation set out the task for the nuclear industry of optimizing VVER operational characteristics as a priority.

State Corporation “Rosatom” builds nuclear power plants in Russia. The scope of nuclear power plant development has been defined until 2020, taking into account the projected power-plant engineering capabilities to produce main equipment for nuclear power plants with typical VVER units annually, and capabilities of nuclear construction power complex to put the main equipment into operation at different sites simultaneously.

The VVER-TOI project is developed on the basis of the design documents worked out for AES-2006, considering the experience gained in development of projects based on VVER technology both in Russia and abroad, such as Novovoronezh NPP-2.

Purpose

VVER-TOI is a new generation III+ Power Unit based on VVER technology,[2] which meets a number of goals using modern information and management technologies.

The VVER-TOI design is intended to improve the competitiveness of Russian VVER technology in international markets; it is oriented to further serial construction of NPP with VVER-TOI both in Russia and abroad.

Tasks

- Develop a typical project for NPP Power Unit based on the optimized technical solutions made for AES-2006.

- Develop power-unit information model and provide its further information support at all the stages of NPP life cycle.

- Develop common information space for the territorially distanced project participants, in particular to make portal and integration decisions.

- Develop modern software for designing and engineering, ensuring transfer of all the required information to the consequent stages of NPP life cycle.

- Develop purchasing, supply and automated identification systems.

- Develop simulation system for Power Unit construction providing an interaction among designing system, equipment purchasing system and construction deadlines control system in the terms of real time.[3]

Main technical-economic indicators

| No. п/п | Indicator | Value |

|---|---|---|

| 1 | Service life, years:

|

60 60 |

| 2 | Power Unit output, MW:

|

1255 3300 |

| 3 | Safe Shutdown Earthquake of intensity on MSK-64 scale:

|

8 9 |

| 4 | Design-Basis Earthquake of intensity on MSK-64 scale | 7 |

| 5 | Time required to provide self-contained plant operation in case of beyond design basis accident, h | 72 |

| 6 | Turbine | Low-speed |

| 7 | NPP construction term from first concreting until physical starting-up (for serial unit), months | 40 |

| 8 | Decrease in estimated cost of the serial Unit construction in comparison with the first Unit of Novovoronezh NPP-2, % | 20 |

| 9 | Decrease in design operation expenditures of the Power Unit in comparison with the fourth Unit of Balakovo NPP, % | 10 |

Project initial requirements

- Stability in the terms of critical external impacts and natural disasters.

- Correspondence to the world accepted rules and regulations.

- Correspondence to the climatic conditions from the tropics up to Northern regions.

- Independence in the terms of external power and water supply sources loss.

Safety assurance principles

Population and environment protection

The radiation safety is arranged and implemented to prevent inadmissible impacts caused by ionizing radiation sources on the materials, population and environment in the area of NPP siting.

The concept of providing radiation and nuclear safety in VVER-TOI project is based on the following:

- requirements provided by domestic safety rules and regulations in force in the field of nuclear-power engineering, which are applicable for the designed power unit considering their further development;

- modern philosophy and safety principles developed by the world nuclear community and reflected in the IAEA Safety Standards;

- materials published by International Nuclear Safety Advisory Group (INSAG) on nuclear safety issues, EUR requirements;

- complex of the technical solutions worked-out and checked through operation considering the efforts targeted at their upgrading, and elimination of the “weak links” revealed during operation;

- verified and certified calculation methods, codes and programs; worked-out safety analysis methodology, reliable database;

- organizational and technical measures to prevent and restrict severe accidents repercussions, which are developed according to the results of investigations in the field of severe accidents;

- experience in development of new generation and increased safety plants;

- to provide low sensibility to the errors and personnel mistaken solutions;

- to ensure low risks of considerable radionuclide emission in case of accident;

- to provide possibility of exercising safety functions without external power supply, as well as making control through “human–machine” interface;

- to ensure conditions required to avoid evacuation of the population living near NPP in case of severe accidents.

Safety barriers

VVER-TOI project shows implementation of the following principles ensuring the modern concept of the repetitive defense in depth:

- to create a number of the consequential barriers preventing emission of the radioactive products, which are accumulated during operation to environment. Nuclear fuel (fuel matrix and fuel-element cladding), boundaries of the coolant circuit, cooling reactor core (reactor vessel, pressurizers, main circulating pumps, steam generator collectors, primary circuit pipelines and connected systems, heat-exchanging steam generator tubes), hermetic fences of the premises with located equipment and reactor plant pipelines inside can serve as the barriers for NPP with VVER.

- high level of reliability caused by implementation of the special requirements to quality assurance and control while designing, manufacturing, installation, keeping the level achieved during operation through control and diagnostics (ceaseless or periodical) of physical barriers conditions, elimination of the revealed defects, damages and failures;

- to establish protective and localizing systems intended for prevention of the physical barriers damage, restriction or mitigation of the radiation repercussions in case of possible infringement of normal operation margins and conditions, and in case of accidents.

NPP protection against external impacts

Natural disasters and human-induced impacts specifying site conditions are accepted taking into account possibility of constructing NPP with VVER-TOI in various geographical regions, as well as in the regions characterized by different human-induced impacts.

The most important impacts, which parameters affected significantly technical solutions on VVER-TOI project are listed below:

- Seismic impacts

- Impacts connected with aircraft crashes

- Air impact waves

- Floods and storms

- Tornadoes

NPP systems and components as a part of the base - case project are developed by reference to the following natural disasters and design human-induced impacts:

- Safe Shutdown earthquake of intensity up to 8 on MSK-64 scale at maximum horizontal acceleration on a free ground surface of 0.25 g

- Design-Basis earthquake of intensity up to 7 on MSK-64 scale at maximum horizontal acceleration on a free ground surface of 0.12 g

- Crash of a 20 t aircraft at a speed of 215 m/s as design initial event

- Crash of a 400 t heavy aircraft at a speed of 150 m/s as beyond design initial event considering fuel fire; to cope with this event the design provides prevention of radionuclide release to environment

- Air impact wave at a pressure of 30 kPa and duration of the compression phase up to 1 s

- Wind maximum design speed up to 56 m/s

Severe accidents control

Modern NPPs are characterized by the unprecedented low risk of ionizing radiation propagation and radionuclide emission to environment. This result is achieved through newest protective and localizing technologies of the safety system. VVER-TOI project shows, as a basis variant, the configuration based on two channel structure of active safety systems without internal backup, and four channel structure of passive safety systems. Profile of the active safety systems is as follows:

- System of fuel pool emergency and planned cooling down and cooling;

- emergency boron injection system;

- steam generator emergency cooling down system;

- Emergency power supply system (diesel-generator set).

Profile of the passive safety systems is as follows:

- passive part of the core emergency cooling system;

- passive core-flooding system;

- water supply system from the fuel pond to primary circuit;

- system of passive heat removal from steam generator;

- primary circuit protection against overpressure;

- secondary circuit protection against overpressure;

- fast-acting pressure reducing station;

- emergency gas-removal system;

- emergency power supply system (accumulators);

- passive system of inner shell leakages filtration.

The accident control facility of the VVER-TOI project includes a corium trap, a unique Russian safety technology, which provides the guaranteed safety control through melt localizing and cooling in the terms of a severe accident at the beyond-vessel stage of core-melt localization. Within the frame of VVER-TOI, there are performed the works directed toward optimization of technical solutions made for corium trap project to decrease cost indicators and justify the corium trap operation efficiency. It is supposed to achieve a considerable decrease in the trap vessel overall sizes and sacrificed materials weight, as well as to transfer to module design of the trap vessel that make it possible to simplify transportation of the large-sized equipment to the site of NPP construction.

Combination of passive and active safety systems provided for in the VVER-TOI project ensures that core will not be destroyed for not less than 72 hours from the moment of severe accident happening in case of any possible scenario. The corresponding technical solutions guarantee that reactor plant will be transferred to safe conditions at any combination of initial events (natural and human-induced) triggering to loss of all the electric power sources. This fact increases considerably the project competitiveness both in foreign and domestic markets of electric power production.[4]

Project key features

Typical project

VVER-TOI is a basis for development of NPP serial construction projects at the sites located within a wide range of natural-climatic conditions, considering the whole spectrum of internal extreme and external human-induced impacts, which are specific for all eventual construction sites. The project is developed to the intent that its application in individual NPP projects would not require change of the main conceptual, engineering and layout solutions, as well as additional safety analysis and other justifying documents to be submitted to the state supervisory authorities for receiving construction licenses.

Innovative designing technologies

- United information space is a multi-platform software and hardware complex intended for control of the engineering data for engineering, designing, as well as arranging communication between territorially-distanced project participants.

- An expanded functional analysis (based on the detail application of IAEA standards) is the practical basis to specify an assignment for automatic performance of NPP technological processes, designing organization-functional operation structure, and grounded calculation of normal-mode ratio.

- MultiD-designing serves as a developed “field-engineering” experience that considerably increases possibility of the project controlling through detail working-out the process solutions on construction and equipment installation.

Upgrading possibility

VVER-TOI power unit circuits, equipment, systems and structures design make it possible to upgrade it allowing for:

- increase annual electric power production (e.g. by ICUF increasing, scheduled and unplanned downtime reducing);

- decrease auxiliary power consumption;

- decrease electric and thermal power losses;

- improve personnel working conditions;

- keep a proper safety level following to toughening requirements provided by regulatory documents and necessity to receive operation permits on a periodical basis during NPP design service life.

Virtual Prototyping Center

Virtual Prototyping Center is a complex of soft-and-hardware facilities making it possible to visualize design and engineering models. It represents a 6-metre-diameter (20 ft) sphere, in which center attendance being at 2-metre (6.6 ft) height at a transparent glass platform can see 3D-format picture. It allows everyone to go into virtual worlds.

The complex practical use includes the following:

- NPP model interactive control;

- planning and design solutions analysis;

- working-out NPP operation, maintenance and repair;

- simulation of the actions to be undertaken in case of emergencies;

- to be used as a testing-area for Crisis Management Center.

At the present moment there are no analogous technical implementations in Russia while designing complicated technological objects. This demonstration method is used only by defense industry, large automobile corporations and aircraft engineering companies.[5]

Deadlines of the project implementation

2009:

- In July 22, 2009 the President Committee for upgrading and development of the Russian economy made a decision on starting the project for development of nuclear technologies in reactor plant within the frame of short-term priority;

- Stage of commencement of the works under the project.

2010:

- Nuclear island and VVER-TOI power unit conceptual model;

- Establishment of the organization being a holder of the base technology provided with modern design and engineering facilities.

2011:

- 3D-design of nuclear island and VVER-TOI power unit;

- Safety justifying calculations.

2012:

- MultiD-project of NPP with VVER-TOI;

- Preparation of a package of the updated normative technical documents to provide usage of new design and construction technologies in the project.

The project has been realized since 2009 and will be completed in 2012.

References

- ↑ (from Russian: Водо-водяной энергетический реактор типовой оптимизированный информатизированный; transliterates as Vodo-Vodyanoi Energetichesky Reactor Tipovoi Optimizirovanniy Informatizirovanniy; Water-Water Energetic Reactor Typical Optimized Informatized), also referred to as AES-2010,

- ↑ "Gen III/III+ Nuclear Reactors RESEARCH NEEDS AND CHALLENGES, FISA" (PDF). Prague. 2009.

- ↑ "OJS "Atomenergoproekt"".

- ↑ A.Yu. Kuchumov, A.Yu. Alaev (2011). "Safety concept of VVER-TOI project, No. 4" (PDF).

- ↑ "Information and Public Relations Department of OJS". Concern Rosenergoatom.