T2 tanker

The T2 tanker, or T2, was an oil tanker constructed and produced in large quantities in the United States during World War II. After the T3s, they were the largest "navy oilers" of the period, some 500 being built between 1940 and the end of 1945. Post war many T2's remained in use, like other hastily built World War II ships pressed into peace time service there were safety concerns. As was found during the war, the United States Coast Guard Marine Board of Investigation in 1952 stated that in cold weather the ships were prone to metal fatigue cracking, so were "belted" with steel straps. This occurred after two T-2s, Pendleton and Fort Mercer, split in two off Cape Cod within hours of each other. Engineering inquiries into the problem suggested the cause was due to poor welding techniques. It was found the steel (that had been successfully used in riveted ship design) was not well suited for the new war time welding construction. The high sulfur content made the steel brittle and prone to metal fatigue at lower temperatures.

Designs

T2 design

The T2 design was formalized by the United States Maritime Commission as its medium-sized "National Defense tanker," a ship built for merchant service which could be militarized as a fleet auxiliary in time of war. MarCom subsidized the excess cost of naval features beyond normal commercial standards. The T2 was based on two ships built in 1938-39 by Bethlehem Steel for Socony-Vacuum Oil Company, Mobilfuel and Mobilube, differing from the Mobil ships principally in the installation of more powerful engines for higher speed. Standard T2s were 501 ft 6 in (152.9 m) in total length, with a beam of 68 ft (20.7 m). Rated at 9,900 tons gross (GRT), with 15,850 long tons deadweight (DWT), standard T2s displaced about 21,100 tons. Steam turbines driving a single propeller at 12,000 horsepower (8,900 kW) delivered a top speed of 16 knots (30 km/h). Six were built for commerce by Bethlehem-Sparrows Point Shipyard in Maryland, only to be taken over by the United States Navy following the attack on Pearl Harbor as the Kennebec class oiler.

T2-A design

Keystone Tankships company ordered five tankers in 1940 from Sun Shipbuilding & Drydock of Chester, PA, based on the T2 but longer and with increased capacity; Marcom would designate this design T2-A. Bigger but faster, they were 526 ft (160.3 m) in total length, displaced about 22,445 tons, and were rated at 10,600 tons gross with 16,300 DWT — yet they attained a top speed approaching 16.5 knots (30.6 km/h). All five were requisitioned by the Navy during the war and converted to fleet oilers as the Mattaponi class.

T2-SE-A1

By far the most common variety of the T2-type tanker was the T2-SE-A1, another commercial design already being built in 1940 by the Sun Shipbuilding Company for Standard Oil Company of New Jersey. They were 523 ft (159.4 m) long, 68 ft (20.7 m) abeam, with 10,448 gross register tons (GRT) and 16,613 DWT. Their (steam) turbo-electric transmission system delivered 6,000 shaft horsepower, with maximum thrust of 7,240 horsepower (5,400 kW), which produced a top-rated speed of about 15 knots (28 km/h) with a cruising range of up to 12,600 miles (20,300 km). After Pearl Harbor, the United States Maritime Commission ordered this model built en masse to supply U.S. warships already in accelerated production, and provide for the fuel needs of US forces in Europe and the Pacific, as well as to replace the tanker tonnage being lost at an alarming rate to German U-boats. 481 were built in extremely short production times by the Alabama Drydock and Shipbuilding Company of Mobile, Alabama, the Kaiser Company at their Swan Island Yard at Portland, Oregon, the Marinship Corp. of Sausalito, California and the Sun Shipbuilding and Drydock Company of Chester, Pennsylvania. During that period, average production time from laying of the keel to "fitting out" was 70 days. The record, however, was held by Marinship, which had the Huntington Hills ready for sea trials in just 33 days.

T2-SE-A2 and -A3

The T2-SE-A2 variation, built only by Marinship of Sausalito, was nearly identical to the T2-SE-A1 version, only with maximum thrust of 10,000 horsepower (7,500 kW) rather than the former’s 7,240. The A3 variation was essentially an A2 built as a Navy oiler from the start, rather than converted later as many A2s were.

T3-S-A1

Despite the confusing T3 designation, the T3-S-A1s built by Bethlehem Sparrows Point for Standard Oil of New Jersey were identical to the original T2s except for having less powerful engines of 7700 hp. 25 of this design were ordered by the Maritime Commission, of which five became Navy oilers as the Chiwawa class.

Notable incidents

Navy service

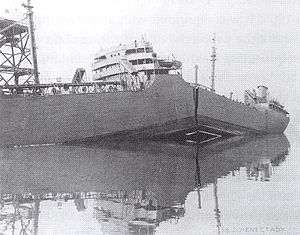

- Schenectady, broke in two in 1943.

At 11pm on 16 January 1943, a few days after completing her sea trials, the 501 ft long T2 tanker Schenectady broke in two amidships while lying at the outfitting dock in the constructors yard in Portland, Oregon, USA. The temperature of the harbor water was about 39°F (4°C) and water conditions were still. The air temperature was approximately 26°F (-3°C) and winds were light. The hull failure was sudden and accompanied by a report that was heard a mile away.

The Schenectady, built by a Kaiser Shipyard, was the first catastrophic T2 hull failure, made all the more impressive by the still conditions under which it occurred. The failure of the Schenectady initiated on the deck between two bulkheads and ran down to the keel (see photo). A defective weld was present in a region of stress concentration arising at a design detail point. Poor welding procedures were cited by the committee investigating the failure as contributory; however, at that time the metallurgical problems were not fully understood.

Commercial service

- Pendleton, broke in two on February 18, 1952

- Fort Mercer, broke in two on February 18, 1952

- Marine Floridian, collided with a drawbridge in Virginia in 1977

- Marine Electric, foundered off the coast of Virginia in 1983

- Delta Conveyor sunk in the Mississippi River adjacent to Delta Bulk Terminal in Convent, Louisiana. Raised in two sections: the bow in early 2003 and the aft section in late 2003.[1]

See also

- Escambia-class replenishment oiler

- List of Type T2 Tanker names

- Liberty ship

- Marine Floridian, a T2 Tanker that in 1977 collided with a drawbridge in Virginia in a spectacular and costly accident.

- Marine Electric, a T2 tanker that sank in a 1983 storm, the investigation of which led to major reforms in ship inspections and safety standards.

- Marine Sulphur Queen, a T2 tanker, lost in the Bermuda Triangle

- Type C1 ship

- Type C2 ship

- United States Merchant Marine Academy

- United States Navy oiler

- V. A. Fogg, a T2 tanker, mistakenly believed to have been lost in the Bermuda Triangle

- Victory ship

References

Notes

- ↑ "Titan Lifts 4000-ton Wreck". International Dredging Review. April 2003. Retrieved 3 March 2015.

Bibliography

- Lane, Frederic Chapin (2001) [1951]. Ships for Victory: A History of Shipbuilding under the U.S. Maritime Commission in World War II. Baltimore: Johns Hopkins Press. ISBN 978-0-8018-6752-1. OCLC 45799004.

- Ship Failure Laid to Steel, Welding New York Times, March 18, 1943

External links

| Wikimedia Commons has media related to T2 tanker. |