Temperature-responsive polymer

Temperature-responsive polymers or thermoresponsive polymers are polymers that exhibit a drastic and discontinuous change of their physical properties with temperature.[1] The term is commonly used when the property concerned is solubility in a given solvent, but it may also be used when other properties are affected. Thermoresponsive polymers belong to the class of stimuli-responsive materials, in contrast to temperature-sensitive (for short, thermosensitive) materials, which change their properties continuously with environmental conditions. In a stricter sense, thermoresponsive polymers display a miscibility gap in their temperature-composition diagram. Depending on whether the miscibility gap is found at high or low temperatures, an upper or lower critical solution temperature exists, respectively (abbreviated UCST or LCST).

Research mainly focuses on polymers that show thermoresponsivity in aqueous solution. Promising areas of application are tissue engineering,[2] liquid chromatography,[3][4] drug delivery[2][5] and bioseparation.[6] Only a few commercial applications exist, for example, cell culture plates coated with an LCST-polymer.

History

The effects of external stimuli on particular polymers were investigated in the 1960s by Heskins and Guillet.[7] They established 32 °C as the lower critical solution temperature (LCST) for PNIPAAm.

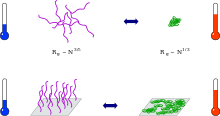

Coil-globule transition

Thermoresponsive polymer chains in solution adopt an expanded coil conformation. At the phase separation temperature they collapse to form compact globuli. This process can be observed directly by methods of static and dynamic light scattering.[8][9] The drop in viscosity can be indirectly observed. When mechanisms which reduce surface tension are absent, the globules aggregate, subsequently causing turbidity and the formation of visible particles.

Phase diagrams of thermoresponsive polymers

The phase separation temperature (and hence, the cloud point) is dependent on polymer concentration. Therefore, temperature-composition diagrams are used to display thermoresponsive behavior over a wide range of concentrations.[10] Phases separate into a polymer-poor and a polymer-rich phase. In strictly binary mixtures the composition of the coexisting phases can be determined by drawing tie-lines. However, since polymers display a molar mass distribution this straightforward approach may be insufficient. During the process of phase separation the polymer-rich phase can vitrify before equilibrium is reached. This depends on the glass transition temperature for each individual composition. It is convenient to add the glass transition curve to the phase diagram, although it is no real equilibrium. The intersection of the glass transition curve with the cloud point curve is called Berghmans point.[11] In the case of UCST polymers, above the Berghmans point the phases separate into two liquid phases, below this point into a liquid polymer-poor phase and a vitrified polymer-rich phase. For LCST polymers the inverse behavior is observed.

Thermodynamics

Polymers dissolve in a solvent when the Gibbs energy of the system decreases, i.e., the change of Gibbs energy (ΔG) is negative. From the known Legendre transformation of the Gibbs–Helmholtz equation it follows that ΔG is determined by the enthalpy of mixing (ΔH) and entropy of mixing (ΔS).

Without interactions between the compounds there would be no enthalpy of mixing and the entropy of mixing would be ideal. The ideal entropy of mixing of multiple pure compounds is always positive (the term -T∙ΔS is negative) and ΔG would be negative for all compositions, causing complete miscibility. Therefore, the fact that miscibility gaps are observed can only be explained by interaction. In the case of polymer solutions, polymer-polymer, solvent-solvent and polymer-solvent interactions have to be taken into account. A model for the phenomenological description of polymer phase diagrams was developed by Flory and Huggins (see Flory–Huggins solution theory). The resulting equation for the change of Gibbs energy consists of a term for the entropy of mixing for polymers and an interaction parameter that describes the sum of all interactions.[10]

where

- R = universal gas constant

- m = number of occupied lattice sites per molecule (for polymer solutions m1 is approximately equal to the degree of polymerization and m2=1)

- φ = volume fraction of the polymer and the solvent, respectively

- χ = interaction parameter

A consequence of the Flory-Huggins theory is, for instance, that the UCST (if it exists) increases and shifts into the solvent-rich region when the molar mass of the polymer increases. Whether a polymer shows LCST and/or UCST behavior can be derived from the temperature-dependence of the interaction parameter (see figure). It has to be noted that the interaction parameter not only comprises enthalpic contributions but also the non-ideal entropy of mixing, which again consists of many individual contributions (e.g., the strong hydrophobic effect in aqueous solutions). For these reasons, classical Flory-Huggins theory cannot provide much insight into the molecular origin of miscibility gaps.

Applications

Bioseparation

Thermoresponsive polymers can be functionalized with moieties that bind to specific biomolecules. The polymer-biomolecule conjugate can be precipitated from solution by a small change of temperature.[6][12] Isolation may be achieved by filtration or centrifugation.

Thermoresponsive surfaces

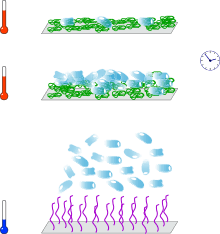

Tissue engineering

For some polymers it was demonstrated that thermoresponsive behavior can be transferred to surfaces. The surface is either coated with a polymer film or the polymer chains are bound covalently to the surface. This provides a way to control the wetting properties of a surface by small temperature changes. The described behavior can be exploited in tissue engineering since the adhesion of cells is strongly dependent on the hydrophilicity/hydrophobicity.[2][13] This way, it is possible to detach cells from a cell culture dish by only small changes in temperature, without the need to additionally use enzymes (see figure). Respective commercial products are already available.

Chromatography

Thermoresponsive polymers can be used as the stationary phase in liquid chromatography.[3] Here, the polarity of the stationary phase can be varied by temperature changes, altering the power of separation without changing the column or solvent composition. Thermally related benefits of gas chromatography can now be applied to classes of compounds that are restricted to liquid chromatography due to their thermolability. In place of solvent gradient elution, thermoresponsive polymers allow the use of temperature gradients under purely aqueous isocratic conditions.[14] The versatility of the system is controlled not only by changing temperature, but also by adding modifying moieties that allow for a choice of enhanced hydrophobic interaction, or by introducing the prospect of electrostatic interaction.[15] These developments have already brought major improvements to the fields of hydrophobic interaction chromatography, size exclusion chromatography, ion exchange chromatography, and affinity chromatography separations, as well as pseudo-solid phase extractions ("pseudo" because of phase transitions).

Thermoresponsive gels

- Covalently linked gels. Three-dimensional covalently linked polymer networks are insoluble in all solvents, they merely swell in good solvents.[16][17] Thermoresponsive polymer gels show a discontineous change of the degree of swelling with temperature. At the volume phase transition temperature (VPTT) the degree of swelling changes drastically. Researchers try to exploit this behavior for temperature-induced drug delivery. In the swollen state, previously incorporated drugs are released easily by diffusion.[18] More sophisticated "catch and release" techniques have been elaborated in combination with lithography[19] and molecular imprinting.[20]

- Physical gels. In physical gels unlike covalently linked gels the polymers chains are not covalently linked together. That means that the gel could re-dissolve in a good solvent under some conditions. Thermoresponsive physical gels, also sometimes called thermoresponsive injectable gels have been used in Tissue Engineering.[21][22][23][24] This involves mixing at room temperature the thermoresponsive polymer in solution with the cells and then inject the solution to the body. Due to the temperature increase (to body temperature) the polymer creates a physical gel. Within this physical gel the cells are encapsulated. Tailoring the temperature that the polymer solution gels can be challenging because this depend by many factors like the polymer composition,[25][26][27][28] architecture[25][26] as well as the molar mass.[27]

Characterization of thermoresponsive polymer solutions

Cloud point

Experimentally, the phase separation can be followed by turbidimetry. There is no universal approach for determining the cloud point suitable for all systems. It is often defined as the temperature at the onset of cloudiness, the temperature at the inflection point of the transmittance curve, or the temperature at a defined transmittance (e.g., 50%).[11] The cloud point can be affected by many structural parameters of the polymer like the hydrophobic content,[25][26][27][28][29] architecture[25][26] and even the molar mass.[27][30]

Hysteresis

The cloud points upon cooling and heating of a thermoresponsive polymer solution do not coincide because the process of equilibration takes time. The temperature interval between the cloud points upon cooling and heating is called hysteresis. The cloud points are dependent on the cooling and heating rates, and hysteresis decreases with lower rates. There are indications that hysteresis is influenced by the temperature, viscosity, glass transition temperature and the ability to form additional intra- and inter-molecular hydrogen bonds in the phase separated state.[31]

Other properties

Another important property for potential applications is the extent of phase separation, represented by the difference in polymer content in the two phases after phase separation. For most applications, phase separation in pure polymer and pure solvent would be desirable although it is practically impossible. The extent of phase separation in a given temperature interval depends on the particular polymer-solvent phase diagram.

Example: From the phase diagram of polystyrene (molar mass 43,600 g/mol) in the solvent cyclohexane it follows that at a total polymer concentration of 10%, cooling from 25 to 20 °C causes phase separation into a polymer-poor phase with 1% polymer and a polymer-rich phase with 30% polymer content.[32]

Also desirable for many applications is a sharp phase transition, which is reflected by a sudden drop in transmittance. The sharpness of the phase transition is related to the extent of phase separation but additionally relies on whether all present polymer chains exhibit the same cloud point. This depends on the polymer endgroups, dispersity, or—in the case of copolymers—varying copolymer compositions.[31]

Examples of thermoresponsive polymers

Thermoresponsivity in organic solvents

Due to the low entropy of mixing, miscibility gaps are often observed for polymer solutions.[10] Many polymers are known that show UCST or LCST behavior in organic solvents.[33] Examples for organic polymer solutions with UCST are polystyrene in cyclohexane,[32][34] polyethylene in diphenylether[35][36] or polymethylmethacrylate in acetonitrile.[37] An LCST is observed for, e.g., polypropylene in n-hexane,[38] polystyrene in butylacetate[39] or polymethylmethacrylate in 2-propanone.[40]

Thermoresponsivity in water

Polymer solutions that show thermoresponsivity in water are especially important since water as a solvent is cheap, safe and biologically relevant. Current research efforts focus on water-based applications like drug delivey systems, tissue engineering, bioseparation (see the section Applications). Numerous polymers with LCST in water are known.[11] The most studied polymer is poly(N-isopropylacrylamide).[41][42] Further examples are poly[2-(dimethylamino)ethyl methacrylate] (pDMAEMA)[25][26][27][28][30] hydroxypropylcellulose,[43] poly(vinylcaprolactame)[44] and polyvinyl methyl ether.[45]

Some industrially relevant polymers show LCST as well as UCST behavior whereas the UCST is found outside the 0-to-100 °C region and can only be observed under extreme experimental conditions.[31] Examples are polyethylene oxide,[46][47] polyvinylmethylether[48] and polyhydroxyethylmethacrylate.[49] There are also polymers that exhibit UCST behavior between 0 and 100 °C. However, there are large differences concerning the ionic strength at which UCST behavior is detected. Some zwitterionic polymers show UCST behavior in pure water and also in salt-containing water or even at higher salt concentration.[50][51] By contrast, polyacrylic acid displays UCST behavior solely at high ionic strength.[52] Examples for polymer that show UCST behavior in pure water as well as under physiological conditions are poly(N-acryloylglycinamide),[53][54] ureido-functionalized polymers,[55] copolymers from N-vinylimidazole and 1-vinyl-2-(hydroxylmethyl)imidazole[56] or copolymers from acrylamide and acrylonitrile.[57] Polymers for which UCST relies on non-ionic interactions are very sensitive to ionic contamination. Small amounts of ionic groups may suppress phase separation in pure water.

It should be noted that the UCST is dependent on the molecular mass of the polymer. For the LCST this is not necessarily the case, as shown for poly(N-isopropylacrylamide).[58][59]

References

- ↑ Allan S. Hoffman, "Intelligent" Polymers in Medicine and Biotechnology, Artificial Organs, 1995, Volume 19, pp 458–467.

- 1 2 3 Mark A. Ward; Theoni K. Georgiou (2011). "Thermoresponsive Polymers for Biomedical Applications". Polymers. 3 (3): 1215–1242. doi:10.3390/polym3031215.

- 1 2 Irene Tan; Farnoosh Roohi; Maria-Magdalena Titirici (2012). "Thermoresponsive polymers in liquid chromatography". Analytical Methods. 4 (1): 34–43. doi:10.1039/C1AY05356F.

- ↑ Pankaj Maharjan; Brad W. Woonton; Louise E. Bennett; Geoffrey W. Smithers; Kirthi DeSilva; Milton T.W. Hearn (2008). "Novel chromatographic separation — the potential of smart polymers". Innovative Food Science and Emerging Technologies. 9 (2): 232–242. doi:10.1016/j.ifset.2007.03.028.

- ↑ A. K. Bajpai, Sandeep K. Shukla, Smitha Bhanu, Sanjana Kankane, Responsive polymers in controlled drug delivery, Progress in Polymer Science, 2008, Volume 33, pp 1088-1118.

- 1 2 Igor Galaev, Bo Mattiasson, Smart Polymers for Bioseparation and Bioprocessing, CRC Press, 2001, ISBN 9780415267984.

- ↑ Michael Heskins; James E. Guillet (1968). "Solution Properties of Poly(N-isopropylacrylamide)". J. Macromol. Sci. Chem. 2 (8): 1441–1455. doi:10.1080/10601326808051910.

- ↑ C. Wu, X. Wang, Globule-to-Coil Transition of a Single Homopolymer Chain in Solution, Physical Review Letters, 1998, Volume 80, pp 4092–4094.

- ↑ S. Vshivkov, A. P. Safronov, The conformational coil-globule transition of polystyrene in cyclohexane solution, Macromolecular Chemistry and Physics, 1997, Volume 198, 3015.

- 1 2 3 Ronald Koningsveld, Walter H. Stockmayer, Erik Nies, Polymer Phase Diagrams, Oxford University Press, Oxford, 2001, ISBN 978-0198556350.

- 1 2 3 V. Aseyev, H. Tenhu, F. M. Winnik, Non-ionic Thermoresponsive Polymers in Water, Advances Polymer Science, 2010, Volume 242,pp 29-89.

- ↑ Jing Ping Chen, Allan S. Hoffman, Polymer-Protein Conjugates II. Affinity precipitation separation of human immunogammaglobulin by a poly(N-isopropylacrylamide)-protein A conjugate, Biomaterials, 1990, Volume 11, pp 631-634.

- ↑ Lee, EL.; von Recum, HA (2010). "Cell culture platform with mechanical conditioning and nondamaging cellular detachment". J Biomed Mater Res A. 93 (2): 411–8. PMID 20358641.

- ↑ Hideko Kanazawa (2007). "Thermally responsive chromatographic materials using functional polymers". J. Sep. Sci. 30 (11): 1646–1656. doi:10.1002/jssc.200700093. PMID 17623446.

- ↑ Eri Ayano; Hideko Kanazawa (2006). "Aqueous chromatography system using temperature-responsive polymer-modified stationary phases". J. Sep. Sci. 29 (6): 738–749. doi:10.1002/jssc.200500485. PMID 16830486.

- ↑ Patrickios, Costas S.; Georgiou, Theoni K. (2003-03-01). "Covalent amphiphilic polymer networks". Current Opinion in Colloid & Interface Science. 8 (1): 76–85. doi:10.1016/S1359-0294(03)00005-0.

- ↑ Rikkou-Kalourkoti, M.; Patrickios, C. S.; Georgiou, T. K. (2012-01-01). Möller, Krzysztof MatyjaszewskiMartin, ed. 6.08 - Model Networks and Functional Conetworks. Amsterdam: Elsevier. pp. 293–308. doi:10.1016/b978-0-444-53349-4.00166-7. ISBN 978-0-08-087862-1.

- ↑ R. Dinarvand, A. D'Emanuele, The use of thermoresponsive hydrogels for on-off release of molecules, Journal of Controlled Release, 1995, Volume 36, pp 221-227.

- ↑ Alexandro Castellanos; Samuel J. DuPont; August J. Heim II; Garrett Matthews; Peter G. Stroot; Wilfrido Moreno; Ryan G. Toomey (2007). "Size-Exclusion "capture and release" separations using surface-patterned poly(N-isopropylacrylamide) hydrogels". Langmuir. 23 (11): 6391–6395. doi:10.1021/la700338p. PMID 17441745.

- ↑ Roongnapa Suedee; Vatcharee Seechamnanturakit; Bhutorn Canyuk; Chitchamai Ovatlarnporn; Gary P. Martin (2006). "Temperature sensitive dopamine-imprinted (N,N-methylene-bis-acrylamide cross-linked) polymer and its potential application to the selective extraction of adrenergic drugs from urine". J. Chromatogr. A. 1114 (2): 239–249. doi:10.1016/j.chroma.2006.02.033. PMID 16530207.

- ↑ Kretlow, James D.; Klouda, Leda; Mikos, Antonios G. (2007-05-30). "Injectable matrices and scaffolds for drug delivery in tissue engineering". Advanced Drug Delivery Reviews. Matrices and Scaffolds for Drug Delivery in Tissue Engineering. 59 (4–5): 263–273. doi:10.1016/j.addr.2007.03.013. PMID 17507111.

- ↑ Klouda, Leda; Mikos, Antonios G. (2008-01-01). "Thermoresponsive hydrogels in biomedical applications". European Journal of Pharmaceutics and Biopharmaceutics. Interactive Polymers for Pharmaceutical and Biomedical Applications. 68 (1): 34–45. doi:10.1016/j.ejpb.2007.02.025. PMC 3163097

. PMID 17881200.

. PMID 17881200. - ↑ Klouda, Leda (2015-11-01). "Thermoresponsive hydrogels in biomedical applications: A seven-year update". European Journal of Pharmaceutics and Biopharmaceutics. Polymers for Drug Delivery Systems. 97, Part B: 338–349. doi:10.1016/j.ejpb.2015.05.017.

- ↑ Ward, Mark A.; Georgiou, Theoni K. (2011-08-03). "Thermoresponsive Polymers for Biomedical Applications". Polymers. 3 (3): 1215–1242. doi:10.3390/polym3031215.

- 1 2 3 4 5 Ward, Mark A.; Georgiou, Theoni K. (2013). "Multicompartment thermoresponsive gels: does the length of the hydrophobic side group matter?". Polymer Chemistry. 4 (6): 1893. doi:10.1039/c2py21032k.

- 1 2 3 4 5 Ward, Mark A.; Georgiou, Theoni K. (2010-02-15). "Thermoresponsive terpolymers based on methacrylate monomers: Effect of architecture and composition". Journal of Polymer Science Part A: Polymer Chemistry. 48 (4): 775–783. doi:10.1002/pola.23825. ISSN 1099-0518.

- 1 2 3 4 5 Ward, Mark A.; Georgiou, Theoni K. (2012). "Thermoresponsive triblock copolymers based on methacrylate monomers: effect of molecular weight and composition". Soft Matter. 8 (9): 2737. doi:10.1039/c2sm06743a.

- 1 2 3 Ward, Mark A.; Georgiou, Theoni K. (2013-07-01). "Thermoresponsive gels based on ABA triblock copolymers: Does the asymmetry matter?". Journal of Polymer Science Part A: Polymer Chemistry. 51 (13): 2850–2859. doi:10.1002/pola.26674. ISSN 1099-0518.

- ↑ Raduan, Norsadiah H.; Horozov, Tommy S.; Georgiou, Theoni K. (2010). ""Comb-like" non-ionic polymeric macrosurfactants". Soft Matter. 6 (10): 2321. doi:10.1039/b926822g.

- 1 2 Georgiou, Theoni K.; Vamvakaki, Maria; Patrickios, Costas S.; Yamasaki, Edna N.; Phylactou, Leonidas A. (2004-09-10). "Nanoscopic Cationic Methacrylate Star Homopolymers: Synthesis by Group Transfer Polymerization, Characterization and Evaluation as Transfection Reagents". Biomacromolecules. 5 (6): 2221–2229. doi:10.1021/bm049755e. PMID 15530036.

- 1 2 3 Jan Seuring, Seema Agarwal, Polymers with Upper Critical Solution Temperature in Aqueous Solution, Macromolecular Rapid Communications, 2012, Volume 33, pp 1898-1920.

- 1 2 A. R. Schultz, P. J. Flory, Phase Equilibria in Polymer-Solvent Systems, Journal of the American Chemical Society, 1952, Volume 74, pp 4760–4767.

- ↑ C. Wohlfarth, Upper Critical (UCST) and Lower Critical (LCST) Solution Temperatures of Binary Polymer Solutions, Polymer Handbook, 87th ed., CRC press, 2006, chapter 13, pp 19-34, ISBN 978-0849304873.

- ↑ J. Hashizume, A. Teramoto, H. Fujita, Phase Equilibrium Study of the Ternary System Composed of Two Monodisperse Polystyrenes and Cyclohexane, Journal of Polymer Science, Polymer Physics Edition, 1981, Volume 19, pp 1405-1422.

- ↑ A. Nakajima, F. Hamada, S. Hayashi, Unperturbed Chain Dimensions of Polyethylene in Theta Solvents, Journal of Polymer Science, Part C: Polymer Symposium, 1966, Volume 15, pp 285-294.

- ↑ R. Koningsveld, A. J. Staverman, Liquid-Liquid Phase Separation in Multicomponent Polymer Solutions. II. The Critical State, Journal Polymer Science, Polymer Physics Editions, 1968, Volume 6, pp 325-347.

- ↑ T. G. Fox, Properties of dilute polymer solutions III: Intrinsic viscosity/temperature relationships for conventional polymethylmethacrylate, Polymer, 1962, Volume 3, pp 111-128.

- ↑ J. M. G. Cowie, I. J. McEwen, Lower critical solution temperatures of polypropylene solutions, Journal of Polymer Science: Polymer Physics Edition, 1974, Volume 12, pp 441-443.

- ↑ Oliver Pfohl, Toshiaki Hino, John M. Prausnitz, Solubilities of styrene-based polymers and copolymers in common solvents, Polymer, 1995, Volume 36, pp 2065-2073.

- ↑ J. M. G. Cowie, I J. McEwen, Influence of microstructure on the upper and lower critical solution temperatures of poly(methylmethacrylate) solutions, Journal of the Chemical Society, Faraday Transactions 1: Physical Chemistry in Condensed Phases, 1976, Volume 72, pp 526-533.

- ↑ S. Fujishige, K. Kubota, I. Ando, Phase Transition of Aqueous Solutions of Poly(N-isopropylacrylamide) and Poly(N-isopropylmethacrylamide), Journal of Physical Chemistry, 1989, Volume 93, pp 3311–3313.

- ↑ M. Heskins, J. E. Guillet, Solution Properties of Poly(N-isopropylacrylamide), Journal of Macromolecular Science: Part A - Chemistry, 1968, Volume 2, pp 1441-1455.

- ↑ A. Kagemoto, Y. Baba, Kobunshi Kagaku, 1971, Volume 28, p 784.

- ↑ Y. Maeda, T. Nakamura, I. Ikeda, Hydration and Phase Behavior of Poly(N-vinylcaprolactam) and Poly(N-vinylpyrrolidone) in Water, Macromolecules, 2002, Volume 35, pp 217-222.

- ↑ H. G. Schild, D. A. Tirrell, Microcalorimetric Detection of Lower Critical Solution Temperatures in Aqueous Polymer Solutions, Journal of Physical Chemistry, 1990, Volume 94, pp 4352-4356.

- ↑ G. N. Malcolm, J. S. Rowlinson, The Thermodynamic Properties of Aqueous Solutions of Polyethylene Glycol, Polypropylene Glycol and Dioxane, Transactions of the Faraday Society, 1957, Volume 53, pp 921-931.

- ↑ S. Saeki, N. Kuwahara, M. Nakata, M. Kaneko, Upper and lower critical solution temperatures in poly (ethylene glycol) solutions, Polymer, 1976, Volume 17, pp 685-689.

- ↑ G. V. Assche, B. Van Mele, T. Li, E. Nies, Adjacent UCST Phase Behavior in Aqueous Solutions of Poly(vinyl methyl ether): Detection of a Narrow Low Temperature UCST in the Lower Concentration Range, Macromolecules, 2011, Volume 44, pp 993-998.

- ↑ R. Longenecker, T. Mu, M. Hanna, N. A. D. Burke, H. D. H. Stöver, Thermally Responsive 2-Hydroxyethyl Methacrylate Polymers: Soluble-Insoluble and Soluble-Insoluble-Soluble Transitions, Macromolecules, 2011, Volume 44, pp 8962-8971.

- ↑ P. Mary, D. D. Bendejacq, M.-P. Mareau, P. Dupuis, Reconciling Low- and High-Salt Solution Behavior of Sulfobetaine Polyzwitterions, Journal of Physical Chemistry B, 2007, Volume 111, pp 7767-7777.

- ↑ Vasantha, Vivek Arjunan; Jana, Satyasankar; Parthiban, Anbanandam; Vancso, Julius G. (2014). "Water swelling, brine soluble imidazole based zwitterionic polymers – synthesis and study of reversible UCST behaviour and gel–sol transitions". Chemical Communications. 50 (1): 46. doi:10.1039/C3CC44407D. PMID 23925439.

- ↑ R. Buscall, T. Corner, The Phase-Separation Behaviour of Aqueous Solutions of Polyacrylic Acid and its Partial Sodium Salts in the Presence of Sodium Chloride, European Polymer Journal, 1982, Volume 18, pp 967-974.

- ↑ Jan Seuring, Frank M. Bayer, Klaus Huber, Seema Agarwal, Upper Critical Solution Temperature of Poly(N-acryloyl glycinamide) in Water: A Concealed Property, Macromolecules, 2012, Volume 45, pp 374-384.

- ↑ Fangyao Liu, Jan Seuring, Seema Agarwal, Controlled Radical Polymerization of N-Acryloylglycinamide and UCST-type Phase Transition of the Polymers, Journal of Polymer Science, Part A: Polymer Chemistry, 2012, Volume 50, pp 4920-4928.

- ↑ N. Shimada, H. Ino, K. Maie, M. Nakayama, A. Kano, A. Maruyama, Ureido-Derivatized Polymers Based on Both Poly(allylurea) and Poly(L-citrulline) Exhibit UCST-Type Phase Transition Behavior under Physiologically Relevant Conditions, Biomacromolecules, 2011, Volume 12, pp 3418-3422.

- ↑ Georg Meiswinkel, Helmut Ritter, A new type of thermoresponsive copolymer with UCST-type transitions in water: poly(N-vinylimidazole-co-1-vinyl-2-(hydroxymethyl)imidazole), Macromolecular Rapid Communications, 2013, Volume 34, pp 1026-1031.

- ↑ Jan Seuring, Seema Agarwal, First Example of a Universal and Cost-Effective Approach: Polymers with Tunable Upper Critical Solution Temperature in Water and Electrolyte Solution, Macromolecules, 2012, Volume 45, pp 3910-3918.

- ↑ Karel Solc, Karel Dusek, Ronald Koningsveld, Hugo Berghmans, "Zero and Off-Zero Critical Concentrations in Solutions of Polydisperse Polymers with Very High Molar Masses, Collection of Czechoslovak Chemical Communications, 1995, Volume 60, pp 1661-1688.

- ↑ Fatema Afroze, Erik Nies, Hugo Berghmans, Phase transitions in the system poly(N-isopropylacrylamide)/water and swelling behaviour of the corresponding networks, Journal of Molecular Structure, 2000, Volume 554, pp 55-68.