Cone Mills Corporation

| Industry | Textiles |

|---|---|

| Fate | Bankruptcy |

| Successor | International Textile Group |

| Founded | 1895 |

| Defunct | 2004 |

| Headquarters | Greensboro, North Carolina |

Key people | Moses H. Cone |

| Products | denim, corduroy, flannel |

Number of employees | appx 10,000 |

Cone Mills Corporation was a world leader in textile manufacturing of corduroy, flannel, denim and other cotton fabrics for most of the 20th century. The company was based in Greensboro, North Carolina and its mills were mostly in North and South Carolina. The company was known as the world's largest producer of denim.[1][2] It was disestablished in 2004.

Early history

The Cone family history begins in 1845 when Herman Kahn (1828–1897), a Jewish-German immigrant, and his sister’s family left their home in Bavaria, Germany for a new life in the United States. Herman changed the spelling of his last name from Kahn to "Cone" almost immediately upon arrival in the United States to become more American.[3]

Herman Cone and his brother-in-law Jacob Adler started a dry goods business in the German-speaking Pennsylvania Dutch town of Jonesboro, Tennessee. Cone & Adler sold the usual items like groceries, hats, boots, and shoes. An exception to this was that they also sold ready-to-wear clothing, unusual in the antebellum South where most clothing was made at home.[4]

Herman met Helen Guggenheimer (1838–1898) in one of his business traveling trips to Lynchburg, Virginia in the early part of the 1850s. She was also from Germany and was Jewish. In 1856, when Helen was eighteen, they got married.[4] Their first child was Moses H. Cone, born in 1857, founder of Proximity Manufacturing Company (original name for the Cone Mills enterprises). Their next was Ceasar, born in 1859, the co-founder.

The family showed in the pre-Civil War 1860 census that their real estate holdings and personal property holdings were an impressive $29,365. By 1861 they closed their business because of the war and put their money instead into real estate.[5] At the end of the war, the family sold some of their real estate to reopen their retail business under the name Adler, Cone, and Shipley.

They engaged in the barter system to trade goods, since cash was then very scarce. They traded their goods for textiles and then resold these in the South for cash. Many times they just took credit on personal property and land. They foreclosed on many of the debts owed them, acquiring hundreds of acres of real estate in the process.[6]

In 1870 the family, who at this point was fairly wealthy, moved to Baltimore, Maryland and started a wholesale grocery business called Guggenheimer, Cone & Company. The family at this point had seven children, five boys and two girls, Claribel and Etta, who gained a reputation as the art-collecting Cone sisters.[7] This business owned by several relative members was ultimately disbanded in 1873 and Herman went into business with his eldest sons, Moses and Ceasar. This new firm was called H. Cone & Sons. The two eldest, Moses and Ceasar, worked with their father in his grocery business while in their teens traveling the Southeast as "drummers" (traveling salesmen). The brothers took and bartered orders from southern merchants for their father's wares. By 1876 the business had expanded to include tobacco and leather goods.[8]

In 1887, Moses and Ceasar Cone invested $50,000 in the C. E. Graham Mill Manufacturing Company of Asheville, North Carolina. They manufactured cotton plaids. In 1893 the mill became Asheville Cotton Mills. In 1888, the brothers invested in Salisbury Cotton Mills of Salisbury, North Carolina. They also invested in Minneola Manufacturing Company of Gibsonville, North Carolina. In 1891, Moses and Ceasar Cone established the Cone Export & Commission Company. The selling agent for southern textiles was called a "plaid trust" by its competitors.[1] Chartered in New Jersey, the company's headquarters were located in New York City and Moses served as its president. In 1893, the Cone brothers then built one of the first textile finishing plants in the South, called Southern Finishing & Warehouse Company.

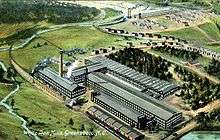

Moses Cone built his first denim manufacturing plant in Greensboro in 1895. The plant was called the Proximity Cotton Mills because of its location to the nearby cotton fields.[1][9] Near the mills "Brother Moses" and "Brother Ceasar" built a facility to serve as the company's headquarters. Ceasar was its first president.[10]

The Cone family, many of whom later were involved in Moses and Ceasar's enterprises, included Carrie (1861–1927), Monroe (1862–1891), Claribel (1864–1929), Albert (1866–1867), Solomon (1868–1939), Sydney M. (1869–1939), Etta (1870–1949), Julius W. (1872–1940), Bernard M. (1874–1956), Clarence N. (1876–1929), and Frederick W. (1878-1944).

Turn of the century

In 1899 Moses and Ceasar partnered with Emanuel and Herman Sternberger of South Carolina to build a flannel production plant called Revolution Mills. In 1905 under Proximity Manufacturing Company the Cone brothers built White Oak Cotton Mills in Greensboro. By 1908 it was the world's largest producer of denim.[11][12] The heavy-duty blue denim manufactured by the mills controlled by Moses gave him the reputation of being "the Denim King."[13][14] The company has produced the denim fabric for Levi Strauss & Company since 1915. They are the exclusive supplier in recent years of the fabric for Levi's brand 501 jeans.[15]

In 1912 the company opened Proximity Print Works.[9] This plant was one of the earliest color cloth printing facilities in the Southern United States. In 1927 the company acquired Cliffside Cotton Mills (manufacturer of terry cloth) and Haynes Plant (producer of chambray). By 1929 they had acquired Holt-Granite Puritan Mills Company of Haw River, North Carolina. They then acquired the corduroy producing Tabardrey Manufacturing Company. By 1932 the Cone company had gained controlling stock of Eno Cotton Mills of Hillsborough, North Carolina. They bought the Florence Mills of Forest City, North Carolina in 1941 and also its subsidiary called American Spinning Company of Greenville, South Carolina.[1]

Company changes name

In 1945 the company merged all its separate mill properties into the Proximity Manufacturing Company. The manufacturing companies, mills, and various subsidiaries owned by the Cones underwent a major reorganization in which the separate business operations of Proximity Manufacturing Company (including Proximity Cotton Mills, Proximity Print Works, White Oak, and Granite), the Cliffside Mills (including the Cliffside and Haynes plants), the Florence Mills (including American Spinning Company), Minneola Manufacturing Company, Salisbury Cotton Mills, Tabardrey Manufacturing Company, and Cone Export & Commission Company, were all reorganized.[2]

Then in 1948 another major merger occurred. Revolution Mills and Proximity Manufacturing Company was consolidated and named Cone Mills Corporation. In 1950 the company announced a merger with the twill and drill manufacturer Dwight Manufacturing Company of Alabama. The following year it purchased the company outright, being the same year the Corporation went public trading on the New York Stock Exchange.[2]

Cone Mills Corporation in 1952 purchased the Union Bleachery of Greenville, South Carolina. They then gained the first license for the sanforizing process granted in the United States.[1]

Involvement with other organizations

( White Oak Branch )

Cone Mills Corporation was involved with Cone Memorial YMCA (the White Oak, Proximity, and segregated branches), Camp Herman, night school, and employment of nurses. They built housing near their mills, both boarding houses and single family homes. Stores sold dairy products and meat was produced on company farms. The company built a school and donated land for churches for each village. The company also instituted a Welfare Office.[9]

They were also involved with state and regional cotton and textile associations, the Mill Workers Mutual Benefit Association, and Summit Avenue Building Company. The company was also associated with the Cone Country Club and founded the Moses H. Cone Memorial Hospital.[2]

From 1958 to 1969 they were involved with the annual Miss North Carolina Pageant. The company provided fabric for wardrobes that were given to each year's winner. They also provided fabric for the presentation gown that each winner wore to represent North Carolina in the annual Miss America Pageant.[16]

Company comes to an end

The textile companies and plants owned and operated in full or in part by the Cone family were Revolution Cotton Mills, Asheville Cotton Mills, Minneola Manufacturing Company, Salisbury Cotton Mills, Cliffside Mills, Eno Cotton Mills, Granite Finishing Works, Tabardrey Manufacturing Company, Florence Mills, John Wolf Textiles, Olympic Products, and American Spinning Company.[1]

The company went private again in 1983 with the threat of a takeover by Western Pacific Industries. At the time the company had twenty-one plants and 10,800 employees. The company then had a value of $385 million.[17][18] In 2003, Cone Mills Corporation filed for Chapter 11 bankruptcy protection. By 2004, all of Cone's assets had been acquired by W. L. Ross and Company and were then combined with what remained of Burlington Industries to form International Textile Group.[19]

The Cone Mill Villages

Mill villages were company-owned towns, built from scratch by textile mills to house their factory workers and their families. In the early 1900s, Cone Mills Inc. built five self-sufficient villages to serve its Greensboro factories. These villages included churches, schools, baseball fields, community centers, and company stores in addition to houses that were leased to mill workers. At their peak, the Cone mill villages covered 450 acres (1.8 km2) and housed 2,675 workers in about 1,500 houses. A separate mill village, East White Oak, housed African-American workers. Thousands of workers and their families made their lives in these “towns within a town” until the company began selling the houses (sometimes to workers) in the late 1940s.[20]

References

- 1 2 3 4 5 6 Cone Mills LLC - company history; Cone Mills Corporation current report 2003 Form 8-K News Release; All About/Denim; The Appeal of Blue -- Now Red or Green -- Jeans

- 1 2 3 4 Cone Mills Corporation - Company Profile, Information, Business Description, History, Background Information on Cone Mills Corporation

- ↑ Noblitt p. 4

- 1 2 Noblitt, p. 5

- ↑ Noblitt p. 6

- ↑ Noblitt, p. 6

- ↑ Noblitt, p. 7

- ↑ Noblitt, p. 8

- 1 2 3 The History of Proximity Cotton Mill and Proximity Print Works

- ↑ Moses H. Cone Memorial Park

- ↑ Noblitt, p. 18

- ↑ A Mansion in the Mountains by Philip Noblitt - page 18

- ↑ Renour, p. 74

- ↑ Blue Ridge Parkway Foundation - The Moses H. Cone Memorial Park; MetroMagazine's NC Business Hall of Fame

- ↑ Cone Mills Corporation chooses BPCS Client/Server version 6.0 to streamline order fulfillment process

- ↑ Inventory of the Cone Mills Corporation Records, 1858-1997

- ↑ Noblitt, p. 3

- ↑ Cone Mills planning to go private

- ↑ International Textile Group Completes Integration of Burlington and Cone

- ↑ Covington, Howard E., Jr. (2008). "Once Upon A City: Greensboro, North Carolina's Second Century," p.43-44. Greensboro Historical Museum,Inc., Greensboro, NC.

Further reading

- Gabriel, Mary, The Art of Acquiring: A Portrait of Etta and Claribel Cone, Bancroft Press 2002, ISBN 1-890862-06-1

- Renouf, Norman, Romantic Weekends the Carolinas & the Georgia Coast, Hunter Publishing 1999, ISBN 1-55650-854-9

- American Council of Learned Societies, Dictionary of American Biography, Scribner publisher 1958, original at University of Michigan library.

- Noblitt, Philip T., A Mansion in the Mountains: The Story of Moses and Bertha Cone and their Blowing Rock Manor, Parkway Publishers 1996, ISBN 1-887905-02-2

- Inventory of the Cone Mills Corporation Records, 1858-1997, in the Southern Historical Collection, UNC-Chapel Hill