Braiding machine

A braiding machine weaves strands of yarn to form rope, reinforced hose, covered power cords, and some types of lace. Materials include Nylon, polypropylene, polyester, polypropylene/polyester blend, and others.

Maypole braiders

Maypole braiders work by a circular weaving process.[1] They were well suited to be driven by the steam engines of the industrial revolution and were common by the beginning of the 20th century being easily powered by electric motors. Common types of braiding machines work in much the same way as the process of decorating a maypole. At the start of decorating a maypole an even number of ribbons tied to the top of the pole. A group of people form a ring about the base of the pole and take a ribbon in hand. Half the people then travel clockwise and the other half counter clockwise. When the people pass one another they pass alternately to the right and to the left. This results in a downward forming braid on the pole. As the braid works its way down the pole, the ribbons become shorter and the angle of forming changes as the braid works lower on the pole. On a standard braiding machine, the supply lines are a constant angle and at a constant tension and hence the output braided product is uniform.

Process

- Fibers are spun into yarn.

- One or more yarns are twisted together to form a strand.

- Strands are wound onto bobbins.

- Bobbins are mounted on carriers.

- Carriers are mounted onto a braiding machine, where the braiding takes place.

Horn gear braider

In a horn gear braider, bobbins of thread pass one another to the left and right on pseudo-sinusoidal tracks, a peg at their bases is driven by a series of so called horn gears. A horn gear consists of a notched disk driven by a spur gear below on the same shaft. These gears lie below the track plate that the bobbin carriers ride on, and an even number of gears must be used as there are always an even number of bobbins. The gears must be driven at multiple points on machines with two or more bobbin sets and cross-shafts are used.

On a vertically oriented machine, the braided thread is taken up above the machine and height and diameter of a guide ring determines the characteristics of the braided product to some degree. On horizontal oriented machines, the braiding track plate and associated bobbins are turned through 90 degrees. This enables large stiff braided cables to be output horizontally so a tall factory building is not required.

Braiding machines, although they have an apparent complex movement of bobbins, are mechanically simple and robust. Modern versions are very reliable and consequently can operate for many hours or even days without attention. This has enabled factories with hundreds of machines to be operated by just a few workers, reducing wages, and making products cheaper and/or profits higher. These modern machines have incorporated electronic controls with automated controls. Although ropes, cords and fishing line are still the core products of most braiding companies there are many other products including webbing, cable shielding and automotive products such as reinforced brake lines.

Some machines use a different system, where the motion of the thread carriers resemble a Teacup Ride.

Square braider

The illustration on the right shows the base plate of a horn gear braider specifically designed to create a square braid from eight strands of yarn.[2]

The braider has two tracks, one shaded in green and one shaded in red. Four bobbin carriers slide along each track. The carriers shaded in green travel around the green loop in the clockwise direction, and the four carriers shaded in red travel around the red loop in the counter-clockwise direction. As the two tracks cross over, the strands twist around each other, making a braid.

The carriers are pushed by four horn gears in the base plate. Each of the horn gears has a gear and a horn on a common shaft. The gears intermesh with each other, with alternate gears traveling in opposite directions. Each horn has four slots for pushing a bobbin carrier. The bobbin carriers get passed along from one horn to the next as they make their way along a track.

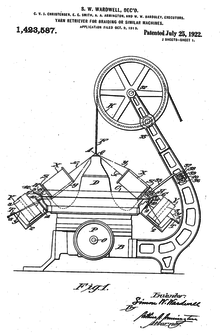

Wardwell Rapid Braider

The speed of a horn gear braider is limited by the effort needed to force bobbin carriers to follow a serpentine path. In 1922, Simon W. Wardwell solved this problem by moving the strands of yarn, instead of the carriers.[3] The carriers follow a simple circular path, while lever arms driven by a cam guide the strands of yarn to their correct places. Because a lever arm has much less mass than a bobbin and carrier, the machine can run faster.

In a YouTube video of a Wardwell braider, the cam is painted yellow.[4] Although these machines run smooth and fast, they must be built for a particular type braid, and are not easily reconfigured.

Track and column braider

In a track and column braider, bobbin carriers follow tracks in a two dimensional array of rows and columns, instead of circular paths defined by horn gears.[5]

Automatic high speed braiding machines

Automatic high speed braiding machines are normally equipped with programmable logic controller (PLC), automatic mass adjusting and motor-driven yarn feeders, so that to make the operation simple and easy. Meanwhile, compared to normal braiding machines, high speed braiding machines save costs from labour, electricity and time.

Products from braiding machines are everywhere in life, like shipbuilding, national defense industry, port operations, high pressure and magnet shielding wires and pipes, decorative ropes and belts, shoelace, elastic ropes and belts, cables, etc.

There are non-traditional machines that have a grid array of thread carriers that under computer control can braid over complex shapes.

References

- ↑ Wulfhorst, Burkhard, Thomas Gries, and Dieter Veit (2006). "Braiding Processes and Machines". Textile Technology. Carl Hanser Verlag GmbH & Co. KG: 188–204. doi:10.3139/9783446433472.007.

- ↑ US patent 4803909, Michael F. Smith, "Apparatus and method for automated braiding of square rope and rope product produced thereby"

- ↑ US patent 1423587, Simon W. Wardwell, "Yarn retriever for braiding or similar machines"

- ↑ YMCORP. "Cam Ring Wardwell Slow Speed". YouTube. Retrieved February 25, 2016.

- ↑ Soares, Carlos (1999). Mechanics of composite materials and structures. Dordrecht Boston, MA: Kluwer Academic Publishers. doi:10.1007/978-94-011-4489-6. ISBN 9780792358701.