Argentium sterling silver

Argentium silver 935 is a modern sterling silver alloy, containing 93.5% silver, in which the traditional alloy (92.5% silver + 7.5% copper) is modified by removing some of the copper and adding the metalloid germanium.[1]

Argentium silver 960 is a high-purity jewellery alloy that meets the hallmarking requirements for the U.K. Britannia standard. The 960 alloy modifies the conventional Britannia silver composition (95.84 silver, balance copper) with the addition of germanium.

Origins and description

Argentium silver is the result of research by Peter Johns at the Art and Design Research Institute (ADRI), School of Art & Design, Middlesex University. The project began in 1990 with research on the effects of germanium additions to silver alloys. Germanium was discovered to impart the following properties to sterling silver:[2]

- Firescale elimination

- High tarnish resistance

- Precipitation hardening and simple heat-hardening properties

- Increased ductility

- Increased thermal and electrical resistance (making alloys suitable for welding and laser forming)

- Environmental advantages (associated with not having to remove or plate over firescale)

Many of these properties significantly affect the traditional methods of working silver. For instance the absence of firescale eliminates tedious and time-consuming steps required by the silver worker using traditional sterling silver. It also eliminates the need for plating the final product which is often done on manufactured items because of the problems introduced by firescale. Tarnish resistance is of significant importance to both silver workers and the wearer of silver jewellery.

Argentium Silver is patented and trademarked by Argentium Silver Company, UK.

Physical properties

Traditional sterling silver has a solidus melting temperature of 1475°F (802°C) and a liquidus flow point of 1650°F (899°C). The solidus of Argentium 935 Sterling silver is 1477°F (803°C) and a liquidus of 1657°F (903°C). The solidus of Argentium 960 silver is 1661°F (905°C) and a liquidus of 1697°F (925°C).

Tarnish testing Argentium silver

Argentium silver alloys are tested using three laboratory tests. These tests are designed to replicate the effects of environmental pollutants and everyday conditions that cause tarnish.[3]

Sulphur test The sulphur test reproduces the effects of sulphur and sulphurous gases found in the atmosphere and everyday substances. This test is based on an ISO (International Organization for Standardization) corrosion testing protocol used within the precious metals industry (ISO 4538:1978).

Perspiration test This test reproduces the effects of perspiration and skin contact with silver alloys. The testing procedure is based on a standardised procedure used in the spectacles industry (ISO 12870:2004, now re-designated ISO 12870:2012).

Ultraviolet test The ultraviolet test determines whether alloys are photosensitive to ultraviolet light. This is especially applicable to silver articles that are on display and exposed to sunlight.

Measuring tarnish resistance

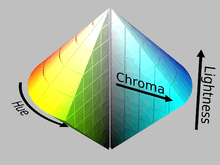

Tarnish resistance is measured through a scientific process using the CIELAB standard colour measurement system. A colorimeter is used to measure the change in surface colour on each test sample after exposure to the tarnish tests. The ‘dark to light’ scale (the central vertical axis in the double-cone colour diagram) is the critical measure used to gauge the degree of tarnish film that is formed on the silver alloy test samples.

Argentium alloys are required to pass predefined levels on the ‘dark to light’ scale, using the CIELAB system. The results from all three tests are combined, using the following weighting coefficients, to give a Tarnishing Index value:

- Sulphur - 0.6

- Perspiration - 0.2

- UV - 0.2

The overall test results are shown in Fig 1.

Firestain resistance

What is firestain? A copper oxide produced when sterling silver articles are heated during production in the presence of air and where the copper in the alloy is oxidised. At red-hot temperatures silver is permeable to oxygen, allowing the copper to be oxidised deep inside the alloy, making it difficult to remove. This oxide is known as firestain (UK) or firescale (USA). Firestain is seen as a dark, purple-grey discoloration.

Why is firestain a problem? Strong acids or abrasive processes are required to remove the unsightly firestain. These procedures not only increase manufacturing costs but also raise environmental and workplace concerns associated with hazardous chemicals. Manufacturers will often simply hide the firestain by plating over it with pure silver. Plating is only a temporary solution as the thin surface layer may quickly wear away and the firestain will be revealed again. The traditional sterling silver watch shown in Fig. 2 has been used for just over a year and shows how quickly a silver-plated surface can be worn away.

How does Argentium silver prevent firestain? The germanium alloyed in Argentium silver oxidises preferentially to the copper. It produces a transparent, self-healing oxide that protects the copper from oxidising and forming firestain. Unlike traditional sterling silver, Argentium silver does not require plating or strong acids to hide or remove penetrating oxides.

Comparison test results The magnified cross-section photographs (Fig. 3) show samples of Argentium silver and traditional sterling silver after being heated in air to a red-hot ‘annealing’ temperature. The penetrating layer of firestain is clearly visible on the traditional sterling sample. No firestain is present on the Argentium silver. (Testing carried out by CATRA - Cutlery & Allied Trades Research Association, UK).

Inside Argentium - How does it work?

Investigations using a Transmission Electronic Microscope (TEM) have shown that a thin dense layer of transparent germanium dioxide (GeO2) forms on the surface of Argentium silver alloys when they are exposed to oxygen. It is this layer that gives Argentium silver its protection against tarnish and firestain. The germanium dioxide layer is self-regenerating; if it is worn off by abrasion, it will reform. Stainless steel uses chromium oxide for protection in a similar way. When compared to the other coating techniques used to protect silver alloys (e.g., rhodium plating and e-coating), the ability to re-form its protective surface layer makes the Argentium silver alloys unique.

The platinum layer deposited by Ion Beam-Induced Deposition (IBID) is required to shield the oxide film only during the TEM process.

References

- ↑ Peter Johns (1997) Firestain Resistant Silver Alloys. Santa Fe Symposium On Jewellery Manufacturing Technology. ISBN 0-931913-25-X

- ↑ Johns, Peter and Davis, Sam (2007) The properties and applications of Argentium (TM) Sterling Silver. In: 31st IPMI Conference (International Precious Metals Institute)

- ↑ Andrea Basso (2010) ‘The Tarnishing of Silver Alloys: Causes and Possibilities’. Santa Fe Symposium on Jewellry Manufacturing Technology ISBN 978-0-931913-40-2

- Eid, Cynthia (September 2006). "Road Testing Argentium Sterling". Art Jewelry: 25–33.

- "Firestain—The Nemesis of the Silversmith". The Goldsmiths' Company 'Technical Bulletin', Issue 3: 10–11. April 2006.

- Haag, Terry (February 2006). "Shine On Silver". Jewelry Arts & Lapidary Journal: 20–24.

- Martin, Eva (February 2006). "Step by Step – Argentium Silver Box Clasp". Jewelry Arts & Lapidary Journal: 36–42.

- Edge, A. M.; V. E. Edge; J. J. Edge (2005). "Investigation on the Quality of Enamel on Germanium Silver". The Goldsmiths' Company 'Technical Bulletin', Issue 2: 8–10.

- Eid, Cynthia (July 2005). "Argentium Sterling Silver". SNAG (Society of North American Goldsmiths) Technical Newsletter. 13.

External links

- Road Testing Argentium Sterling by Cynthia Eid

- The Argentium Storey (video)

- ArgentiumSilver.com (requires Adobe Flash)

- Argentium.eu (offizielle German Site)

- Society of American Silversmiths

- US Patent 6,168,071